THE FUTURE IS FOR EVERYONE: THE CONCEPT OF EMCO INDUSTRIAL TRAINING

Industrial Training provides the best possible conditions for successful training. The training concept not only includes Concept machines and Software, such as specially developed CAD/CAM Software, but also training resources designed to compliment them perfectly. , the concept behind EMCO Industrial Training provides the best possible conditions for successful training. It is based on a modular principle which can easily be adapted to the needs and requirements of particular companies and partners. The training concept not only includes Concept machines and Software, such as specially developed CAD/CAM Software, but also training resources designed to compliment them perfectly – the Courseware.

+ Learn More

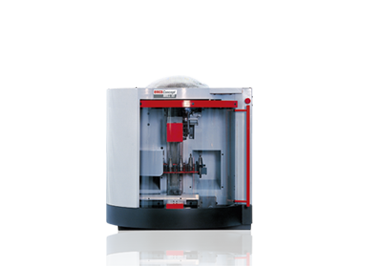

Concept Mill 55

PC-controlled 3-axis Milling Machine for universal CNC Training

Up to 9 CNC controls on 1 machine applicable

Infinitely adjustable main drive

Automatic 8 station tool turret

High-resolution axis motors

Electromechanical tailstock

Robotic interface for integration into FFS/CIM systems

Work Area:

Travel in X/Y/Z: 190/140/260 mmDistance spindle nose: 77 - 337 mm

Number of axes (basic machine): 3rd (4th axis optionally)

Rapid motion speeds in X/Y/Z: 2 m/min

Work feed X/Y/Z: 0-2 m/min

Feed force in X/Y/Z: 800/800/1000 N

Clamping area: 420 x 125 mm

Max. table load: 10 kg

+ Learn More

Watch the video

Concept Mill 105

Up to 9 CNC controls on a machine usable

10 times tool drum with directional logic

Engraving spindle attachment

NC-part apparatus as an optional fourth axis

DNC robotics interface

EMCO EASY CYCLE control integrated

Work Area:

Travel in X/Y/Z: 200 / 150 / 250 mmDistance spindle nose: 95 - 245 mm

Rapid motion speeds in X/Y/Z: 5 m/min

Work feed X/Y/Z: 0 - 5 m/min

Feed force in X/Y/Z: 2000 N

Clamping area: 420 x 125 mm

Max. table load: 10 kg

+ Learn More

Concept Mill 260

Tool magazine with SK30 DIN69871

Up to 5 CNC controls on 1 machine applicable

20 times tool drum with double-gripper

All axes equipped with servo drive motors

Rotary table as an optional fourth axis

DNC robotic interface

Work Area:

Travel in X/Y/Z: 350/250/300 mmDistance spindle nose: 120 - 420 mm

Rapid motion speeds in X/Y/Z: 24 m/min

Work feed X/Y/Z: 0-10 m/min

Feed force in X/Y/Z: 3000

Clamping area: 520 x 300 mm

Max. table load: 100 kg

+ Learn More

Concept Turn 60

Most compact table-top CNC turning machine

According to the latest safety standards

Industry-standard inclined-bed design

High resolution axis motors

Infinitely adjustable main drive

Automatic 8-position tool turret

Profile rail guides (linear guides)

Premium industrial components

Safety technology according to the latest lathes standard

Manual tailstock - option

Work Area:

Travel in X/Y/Z: 60/280 mm (X/Z)Bar diameter: 15 mm

Max. part length: 215 mm

Swing over bed: 130 mm

Rapid motion speeds in X/Y/Z: in X/Z: 3 m/min

Work feed X/Y/Z: 0 - 2 m/min

Feed force in X/Y/Z: 1000 N

+ Learn More

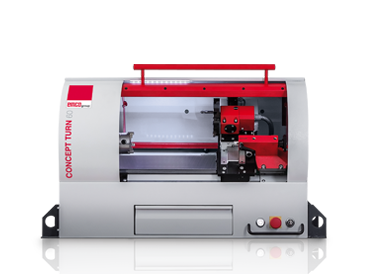

Concept Turn 105

Infinitely variable main drive

8-station tool changer

High-resolution axis motors

Pneumatic tailstock

Automatic clamping device

Up to 9 CNC controls on a machine usable

Robotic Interface for integration into FMS and CIM systems

Work Area:

Travel in X/Y/Z: 55 / - / 172 mmBar diameter: 18 mm

Max. turning diameter: 75 mm

Max. part length with tailstock: 121 mm

Swing over bed: 180 mm

Tool cross-section for outer machining: 12 x 12 mm

Tool cross-section for inner machining: Ø 16

Rapid motion speeds in X/Y/Z: 5 m/min

Work feed X/Y/Z: 0-5 m/min

Feed force in X/Y/Z: 2000 N

+ Learn More

Concept Turn 260

Easy2control user interface with 21,5" touch screen

Integrated industrial PC with network- and USB interface (front)

Various WinNC controls applicable

State of the art drive technology, servomotors with absolute encoders

12 x tool magazine (VDI 16)

6 driven tools

High precision C axis

DNC robotic interface

Work Area:

Travel in X/Y/Z: 100/300 mmBar diameter: 25.4 mm

Max. turning diameter: 85 mm

Max. part length with tailstock: 255 mm

Swing over bed: 250 mm

Tool cross-section for outer machining: 12 x 12 mm

Tool cross-section for inner machining: Ø 16

Rapid motion speeds in X/Y/Z: 15 / - / 24 m/min

Work feed X/Y/Z: 0 - 12 m/min

Feed force in X/Y/Z: 3000 / - / 3500 N

+ Learn More

Concept Turn 460

Interchangeable control key board and integrated industrial PC with network and USB interface (front)

Thermostable head stock with high drive power and C axis

12 x tool magazine with up to 6 driven tools

Synchronized main spindle

C axis with max. 1000 rpm

Programmable part collecting device

Various clamping device and tool holder package

Work Area:

Travel in X/Y/Z: 160/ - / 510 mmBar diameter: 45 mm

Max. turning diameter: 220 mm

Distance spindle nose: 510 mm

Tool cross-section for outer machining: 20 x 20 mm

Tool cross-section for inner machining: Ø 32

Rapid motion speeds in X/Y/Z: 24/-/30 m/min

Work feed X/Y/Z: 0 - 15 m/min

Feed force in X/Y/Z: 4000 / - / 6000 N

+ Learn More

WINNC

The unique concept of the interchangeable control can be fitted in all Concept machines. In doing so, the student is trained on all CNC industry controls that are common on the market. Up to nine different control units can be installed and taught on one single machine.

SINUMERIK OPERATE 840D SL

FANUC SERIES 31i

HEIDENHAIN TNC 426/430

FAGOR 8055

EMCO EASY CYCLE

SINUMERIK 810D/840D

+ Learn More

ACCESSORIES

WIN3D - VIEW

3D graphic simulation with collision control; for turning and milling

EASY2CONTROL

On-screen keyboard

ROBOTIC

Connecting a machine to FMS-CIM systems

DNC

Remote control of a machine via a software protocol

+ Learn More

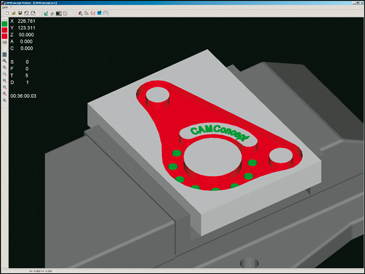

CAMCONCEPT

CAMConcept is innovative software for complete CAD/CAM and CNC training, from design to manufacture. CAMConcept incorporates both the functions of a professional CAD/CAM system and the advantages of a special training program for machining technology. All core CAD program functions are available. Graphic displays of CNC cycles allow quick programming, while simulations and collision checks ensure that control programming is safe. The 3D simulations make it perfect for training at programming stations, and also for making complex turning and milling work pieces simple to produce any time. With its many functions, user-friendly operation and clear structure, CAMConcept is one of the leading software systems in the field of training.

+ Learn More