Designed to overcome the strength limitations of other 3D printed materials, the MarkForged 3D printers are the world's first 3D printers designed to print composite materials. Now you can print functional parts, tooling, and fixtures with a higher strength-to-weight ratio than 6061-T6 Aluminum. The MarkForged 3D Printers uses a patent pending Composite Filament Fabrication (CFF™) process to 3D print continuous strand carbon fiber, Kevlar®, and fiberglass. Utilizing the CFF™ print head and one FFF (Fused Filament Fabrication) print head, the MarkForged 3D Printers can create astonishingly robust parts by reinforcing MarkForged's special blend of nylon with continuous fiber filaments.

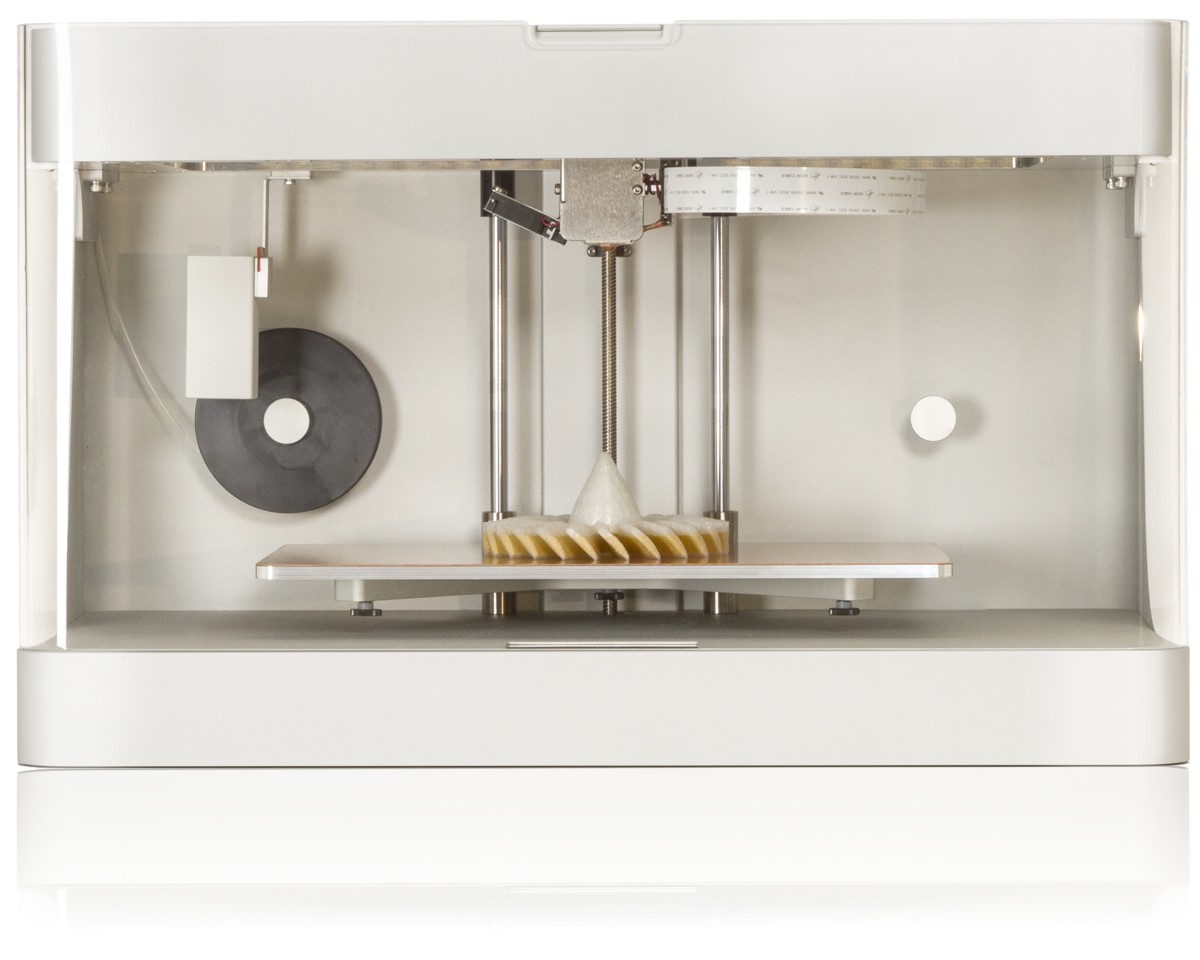

ONYX Series

Welcome to the best, most accessible desktop 3D printer designed uniquely to print beautiful carbon black parts. Start with the Onyx One and create parts for a wide variety of applications using our acclaimed Onyx chopped carbon fiber filament. Step up to the Onyx Pro for the impressive strength of adding continuous fiberglass for strong composite parts.

No other 3D printer on the market is designed from the ground up - hardware, software, and materials - to uniquely create chopped carbon fiber parts – a revolutionary material with beautiful surface finish, stiffness and temperature tolerance. We've designed this to simply work the first time and every time, so you will love to use it.

100 micron Layer Height

ONYX PRO - $6,999.00 (US Dollars)

The Onyx Pro, with a second print head exclusively for continuous fiberglass, is your entry to seriously strong reinforced composite parts that Markforged is known for. Comes with access to cloud Eiger software, 800cc Onyx spool, 50cc Fiberglass, extra print bed!

THE MARK TWO

The Mark Two combines Markforged's unique continuous carbon fiber reinforcement with workhorse reliability for the strongest, most versatile parts in our portfolio. It is the only printer in the industry that enables you to go from CAD to beautiful, end-use strong parts in hours.

With your choice of reinforcement and plastics, remove the time, hassle and design iterations and put your parts to use right off the printer engineered with the right material for any job.

High-Strength Printing

By reinforcing your parts with composite fiber while 3D printing them, The Mark Two achieves unparalleled strength, stiffness and durability in its printed parts.

Range of Materials

In addition to printing Nylon, the Mark Two prints materials that no other 3D printer can, like Carbon Fiber, Fiberglass and Kevlar.

Easy-To-Use

We built our own 3D printing software that comes with The Mark Two. Printing a part to be flexible or strong is easy and intuitive.

Touchscreen Interface

The Mark Two has a built in touchscreen that makes it easy to connect to wifi, start prints and manage your printer.

Build Volume

320 mm x 132 mm x 154 mm

Included with printer

Mark Two printer with access to cloud Eiger software

800cc Onyx spool

800cc Nylon spool

100cc Carbon Fiber

100cc Fiberglass

100cc HSHT Fiberglass

100cc Kevlar

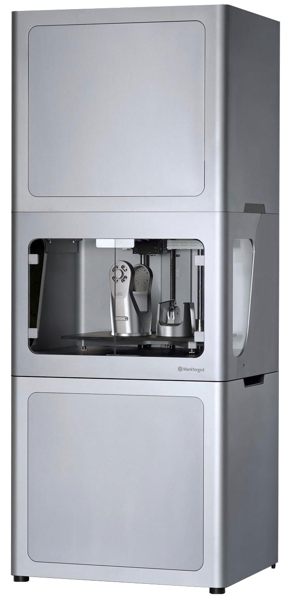

THE MARK X

Uncompromised Strength, Precision and Beauty

The Mark X is the most powerful 3D printer on the market. With industrial-scale printing of incredibly strong parts and first ever precision sensing systems, the Mark X is destined to be the must-have printer for every manufacturer.

This printer combines the benefits of Markforged's unique fiber reinforcement for parts as strong as metal with advanced "build as designed" sensors and the beautiful surface finish of Onyx. The Mark X will empower you to take any design concept and make it a reality.

Large Prints, High-Resolution

The large build volume of the Mark X makes it ideal for robotics, automotive parts, functional prototypes and prosthetics. With 50 micron resolution layer height, your parts will come out of the printer with a beautiful surface finish approaching the look and feel of injection molding.

Build Volume

WIDTH - 330 mm

DEPTH - 250 mm

HEIGHT - 200 mm

Layer Height

50micron

In-Process Inspection

The Mark X gives you breakthrough quality and precision in 3D printing. Scan your parts mid-print using our cloud-based Eiger software and a laser displacement sensor affixed to the print head. Ensure dimensional accuracy at the most critical tolerances at any point in your print.

1 micron Measurement Accuracy!

50 micron Scanning Resolution!

Print As-Designed Parts With Known Precision And Tolerance

Define a tolerance specification in Eiger, our cloud based 3D printing software, and the Mark X will scan your part while it's printing to ensure that it always meets the spec. If an error is detected you will be alerted and can choose to cancel the print remotely, saving time and material.

Build Volume - 330 mm x 250 mm x 200 mm

Included with printer

Mark X printer and cabinet with access to cloud Eiger software

800cc Onyx spool

800cc Nylon spool

150cc Carbon Fiber

150cc Fiberglass

150cc HSHT Fiberglass

150cc Kevlar

One extra print bed (2 total)

Extra nozzles

THE METAL X

Say Hello To ADAM

ATOMIC DIFFUSION ADDITIVE MANUFACTURING

Speed time from design to strong metal parts with this accessible and compact process. ADAM prints your part using a bound metal powder rod that transforms into a dense metal part in one easy step. Bulk sintering provides crystal growth through all axes giving your parts excellent mechanical properties in all directions.

ADAM also enables the creation of unique geometries such as closed-cell honeycomb infill. Parts can be printed like the structure of bones - a closed cell inner core encased in a solid outer shell. This geometry is not possible using traditional subtractive manufacturing processes or DMLS.

Large Prints, High-Resolution

The build volume of the Metal X gives automotive, industrial, aerospace and other industries a new way to rapidly create key components, custom pieces and spare parts. With 50 micron resolution layer height, your parts will come out of the printer with precision details that further resolve after the sintering process.

Build Volume

WIDTH - 250 mm

DEPTH - 220 mm

HEIGHT - 200 mm

Layer Height

50micron

In-Process Inspection

The Metal X gives you breakthrough quality and precision in 3D printing. Scan your parts mid-print using our cloud-based Eiger software and a laser displacement sensor affixed to the print head. Ensure dimensional accuracy at the most critical tolerances at any point in your print. 1 micron Measurement Accuracy!50 micron Scanning Resolution!

Print As-Designed Parts With Known Precision And Tolerance

Define a tolerance specification in Eiger, our cloud based 3D printing software, and the Mark X will scan your part while it's printing to ensure that it always meets the spec. If an error is detected you will be alerted and can choose to cancel the print remotely, saving time and material.

Build Volume - 2500 mm x 220 mm x 200 mm

Materials

17-4 Stainless Steel

303 Stainless Steel

6061 Aluminum (Beta)

7075 Aluminum (Beta)

A-2 Tool Steel (Beta)

D-2 Tool Steel (Beta)

IN Alloy (Inconel) 625 (Beta)

Titanium Ti-6Al-4V (Beta)